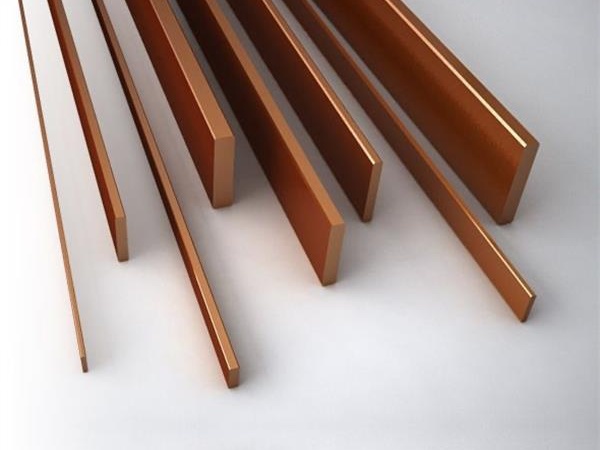

Copper busbar, also known as busbar or copper bar, is a long conductor made of copper material with a rectangular or chamfered (rounded) cross-section. It plays a role in conveying current and connecting electrical equipment in circuits, and has been widely used in electrical equipment, especially in complete power distribution devices. So, do you know how to choose copper bars?

1. Selection method

- Generally, the width of the copper busbar should be the same as the width of the output terminal of the circuit breaker. On the direct load side, the thickness of the busbar can be appropriately reduced to meet the requirements; When connecting the branch busbar to the circuit breaker, the busbar punching is a circular hole for connection. The MNS/GCK branch zero bar does not need to be made when entering and exiting from the bottom, but must be made when entering and exiting from the top.

- The selection of high-voltage busbar copper bars mainly refers to one data, thermal stability, which needs to meet the short-term withstand current.

- The selection of low-voltage busbar is based on the rated current calculated by the transformer. For example, for a 1000KVA transformer, let's first calculate its low-voltage side current: 1443A. Next, you can directly check the current carrying table of the busbar. As can be seen from the current carrying table, an 80 * 8 copper bar can meet the requirements.

- The selection of copper bars also needs to consider the dispersion coefficient. The dispersion coefficient is to consider the subsequent load and will not be used simultaneously. The more circuits there are, the smaller the dispersion coefficient.

- The contact surface between the copper bar and electrical components should be flat and smooth, and the edges and holes of the connectors should be free of burrs and unevenness. After bending the copper bar, there should be no cracks or serious wrinkles. The height of wrinkles should not exceed 1mm, and the bending radius should generally not be less than twice the thickness of the busbar. On the premise that the copper bar does not crack or wrinkle severely after bending, the bending radius is allowed to be equal to the thickness of the busbar.

2. The current carrying capacity of copper bars

Firstly, everyone should understand that the installation of copper bars inside the cabinet can be divided into two forms: horizontal and vertical. The current carrying capacity of vertical bars is slightly higher than that of horizontal bars, so the main busbar of the distribution cabinet is mostly vertical. There are also copper bars, and the current carrying capacity of copper wires varies with the ambient temperature. Here, we mostly use an ambient temperature of 35 degrees Celsius. At different ambient temperatures, the current carrying capacity obtained by looking up the table needs to be multiplied by the correction coefficient at different ambient temperatures to obtain the current carrying capacity at different ambient temperatures. The higher the temperature, the lower the current carrying capacity.

The above is the answer on how to choose copper bars, hoping to be helpful to everyone. Due to the superior conductivity of copper compared to aluminum, copper bars have been widely used in electrical equipment, especially in complete power distribution devices; Generally, copper bars are used for the A, B, C, N phase busbars and PE busbars in the distribution cabinet; Copper bars are generally marked with phase color letters or coated with phase color paint during use. The identification of phase A copper bars is yellow, phase B copper bars are green, phase C is red, phase N is light blue, and PE bus bars are yellow green dual colors