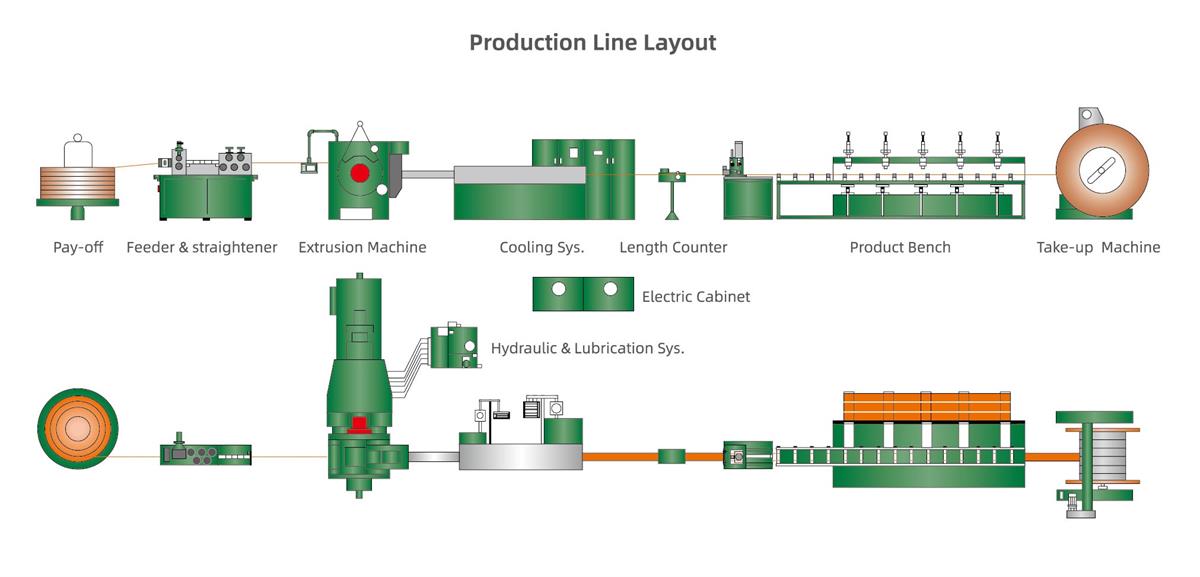

Copper Busbar Extrusion Machine offers an ideal solution to make copper busbars, and other types of copper products by changing the extrusion die. The continuous rotary extrusion line supports using oxygen-free copper rod as the feedstock to produce copper busbar and other types of copper strip with maximum width of 350mm. The feedstock can be conveniently prepared by using continuous casting machines. This range of continuous rotary extrusion machinery is designed with an effective cooling system which not only cools the extruded products but also the tools and components of the copper extruding machine. Thus, the copper busbar production line and its key components have long lifespan and low maintenance.The extruded copper products are widely used in electric motors, power distribution cabinets, transformers, etc.

| Model | Extrusion Wheel Diarneter(mm) | Main Motor Power(kw) | Rod Diameter(mm) | Maximum Width of Product | Product Rod Diarneter(mm) | Product Cross-Sectional Area(mm2) | Output(kg/h) |

| MTLJ350 | 350 | 160 | 16 | 100 | 4.5-50 | 15-1000 | 780 |

| MTLJ350H | 350 | 200 | 16 | 100 | 4.5-50 | 15-1000 | 950 |

| MTLJ400 | 400 | 250 | 20 | 170 | 8~90 | 75-2000 | 1200 |

| MTLJ400H | 400 | 315 | 20 | 170 | 8~90 | 75-2000 | 1500 |

| MTLJ500 | 500 | 355 | 25 | 260 | 12-100 | 300-3200 | 1800 |

| MTLJ630 | 630 | 600 | 30 | 320 | 12-120 | 600-6400 | 2800 |

Finished products by Copper Busbar Extrusion Machine can be: