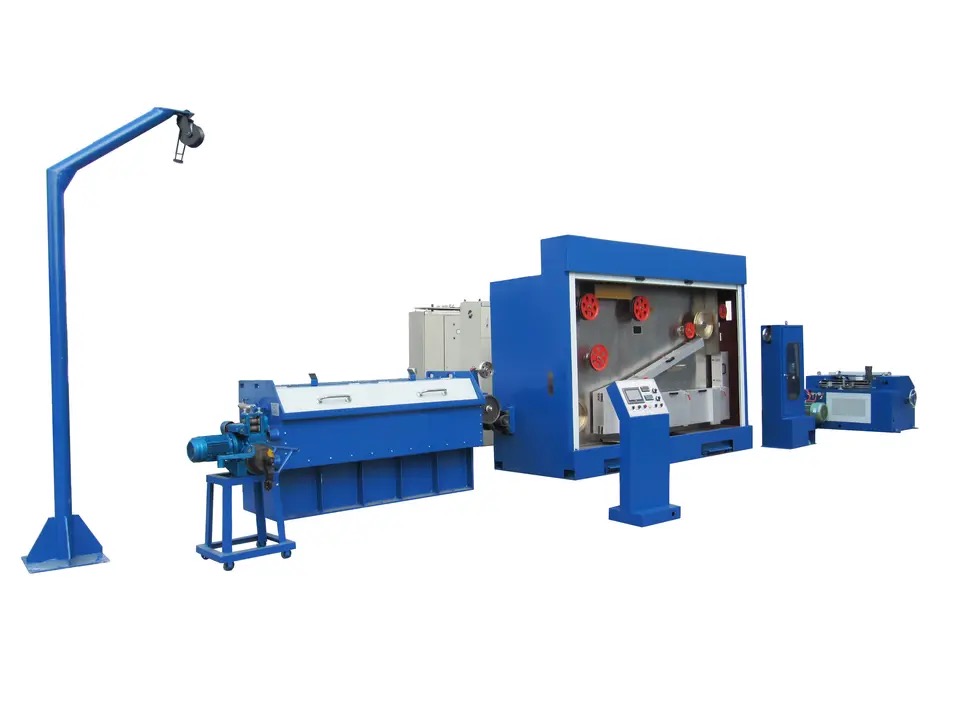

Copper Rod Breakdown Machine with annealer is used to draw copper rod from Ø 8 mm to Ø 1.2~4.0 mm(drawing aluminium wire from 9.5mm to 1.7~4.8mm), which can be continuous annealed before the outlet wire wound by the dual takeup device or coiler.

Components:Pay-off stand, main drawing machine, continuous annealer(for copper wire only) , tension box, automatic dual take-up device(or coiler according to customer), wire pointer and stripper, electrical control system, etc.

| Item | MLHT450/9 | MLHT450/11 | MLHT450/13 |

| Inlet Wire Dia.(mm) | Ø 8 | Ø8 | Ø 8 |

| Outlet Wire Dia.(mm) | Ø 2.0~4.0 | Ø 1.5~4.0 | Ø 1.2~4.0 |

| Max Die No. | 9 | 11 | 13 |

| Drawing Capstan Dia.(mm) | 450 | ||

| Max. Line Speed(mm) | 20 | 22 | 25 |

| Main Motor Power(KW) | 280 | 280 | 280 |

| Annealer Power | 60V×5000A(6000A) | ||

| Drawing Capstan | Coated with tungsten carbide | ||

| Dual Takeup Standard(mm) | PND500/630 | ||

| Traversing Type | Motor type | ||

| Lubrication Type | Immersion and spraying | ||

| Machine type | LHT400/13 | LHT400/11 | LHT400/9 | LHT400/8 |

| Max. Inlet Dia. (mm) | Ф8 | |||

| Outlet Dia. ( mm ) | Ф1.2~Ф3.2 | Ф1.6~Ф3.2 | Ф2.3~Ф3.2 | Ф2.6~Ф3.2 |

| Max. Die No. | 13 | 11 | 9 | 8 |

| Max. Line speed (M/S) | 20 | 18 | 12 | 12 |

| Body structure | Ironed cast | |||

| Transmission type | By high precision grinding gear | |||

| Fix speed capstan Dia.(mm) | Ф400 | |||

| Drawing drum | Coated by tungsten | |||

| Main motor power (KW) | 160 | 132 | 132 | 132 |

| Lubrication Type | Immersion | |||

| Optional Equipment | 1. 350T continuous annealing device | |||

| 2.Double take-up | ||||

| 3.Coiler | ||||

| 4.QD630 Single take-up | ||||

| Optional Function | Fast change die system | |||

| 350T On-line continuous annealing device | ||||

| Type | 350T | |||

| Machine Structure | (horizontal type) | |||

| Annealing Wheel Dia. (mm) | Ф350 | |||

| Annealing Wire dia. (mm) | Ф1.2~Ф3.2 | |||

| Annealing Protection Type | Steam or nitrogen | |||

| Annealing Voltage | 0~60V | |||

| Annealing Current | 0~4500A | |||

Finished products by Copper Rod Breakdown Machine With Annealer machine can be: