This production line adopts the advanced fire refining technology to produce the φ8MM bright low-oxygen copper rod which is meet the international standards in the continuous casting line.

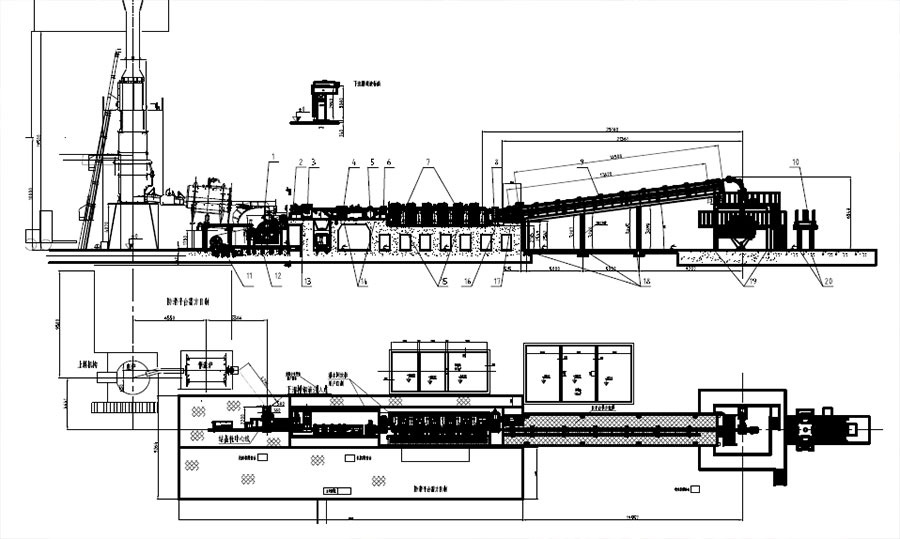

The production line is composed by the melting furnace, holding furnace, five wheel continuous casting machine, rolling shear machine, straightening machine, trimming machine, continuous rolling mill, lubrication system, cooling deoxidization system, coiler and electrical control system etc.

The crystallization wheel adopts four sides cooling and the casting ingot is compact and uniform.

The rolling mill adopts 2 roller stand with oil and emulsion separation system. It is convenient for operation, maintenance and has long service life.

The whole production line adopts IPC+HMI+PLC control with auto synchronization, secure storage of process data and real time display of operating condition.

12T/H,18T/H and 25T/H are available for customer's choice.

| Type | MLZ-12T | MLZ-18T | MLZ-25T |

| Cu Rod Diameter | 8 | 8 | 8 |

| Rolling Pass | 12 | 12 | 13 |

| Capacity(T/H) | 12-15 | 18 | 20-25 |

| Rolling Mode | 2 | 2 | 2 |

| Melting Furnace Output(T/H) | 16 | 20 | 28 |

| Holding Furnace Capacity(T) | 10 | 10 | 15 |

| Furnace Energy | Natural Gas | Natural Gas | Natural Gas |

1) When using cathode copper as raw material

Cathode copper → Vertical furnace → Holding furnace, Launder → Pouring groove → 5-wheel Casting Machine → Front haulage device → Rolling Shear → Straightening and Burring Machine → Feeding Device → Two roller continuous rolling machine → Reduction and Cooling Device → Coiling device → Hydraulic Package device.

2) When scrap copper is used

Scrap copper → Reverberating furnace → (Melting, oxidation and refining) → Pouring groove → 5-wheel casting machine → Front haulage → Rolling shear → Straightening machine (second cooling → Edge milling machine → Burring machine → Continuous rolling mill → Reduction and cooling device → Back haulage→ Coiler

Finished products by Copper Rod Continuous Casting and Rolling Machine can be: