Oxygen free copper rod upcast machine(copper rod upward continuous casting machine) uses cathode copper or scrap copper as raw material, to produce oxygen-free copper rod/ strip(foil billet)/tube.

| Model | Strand | Diameter(mm) | Annual Capability | Furnace Structure | Power Consumption | Installation Capacity |

| MULZ-1000T | 2 | 12.5-20 | 1000 tons | 3 body (2 melting, 1 holding ) | 100kw | 160KVA |

| MULZ-2000T | 4 | 12.5-20 | 2000 tons | 3 body (2 melting, 1 holding ) | 160kw | 220KVA |

| MULZ-3000T | 6 | 12.5-20 | 3000 tons | 3 body (2 melting, 1 holding ) | 220kw | 300KVA |

| MULZ-5000T | 10 | 12.5-20 | 5000 tons | 3 body (2 melting, 1 holding ) | 290kw | 330KVA |

| MULZ-6000T | 12 | 12.5-20 | 6000 tons | 3 body (2 melting, 1 holding ) | 300kw | 350KVA |

| MULZ-8000T | 14 | 12.5-20 | 8000 tons | 3 body (2 melting, 1 holding ) | 400kw | 500KVA |

| MULZ-10000T | 16 | 12.5-20 | 10000 tons | 3 body (2 melting, 1 holding ) | 450kw | 600KVA |

| MULZ-12000T | 20 | 12.5-20 | 12000 tons | 3 body (2 melting, 1 holding ) | 480kw | 600KVA |

| MULZ-15000T | 24 | 12.5-20 | 15000 tons | 3 body (2 melting, 1 holding ) | 700kw | 900KVA |

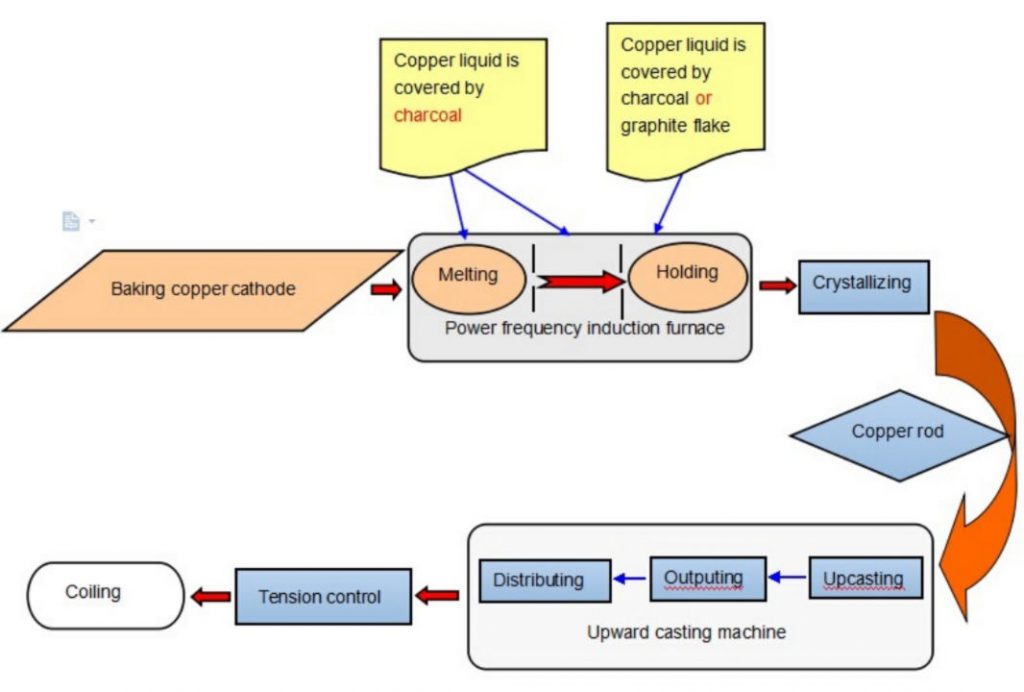

The unit melts cathode copper or scrap copper into liquid through the power frequency induction furnace, insulates it from the air through the charcoal covered on the surface (to avoid the oxidation of the copper liquid) and controls the temperature of the copper liquid in the holding furnace.

The copper liquid of the continuous caster crystallizes rapidly in the crystallizer and continuously produces copper rods.

Finally, it is packaged into products through the double head rod bending machine and other auxiliary equipment.

Finished products by upcasting machine can be: