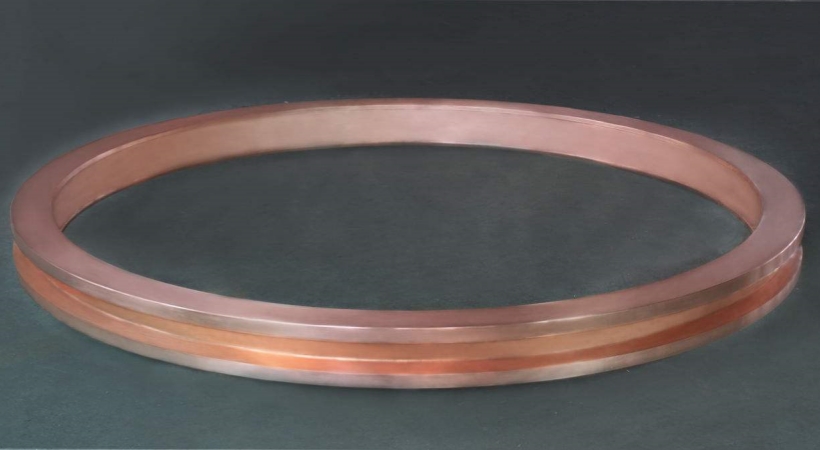

Crystallizing wheel is in type of “H”, on every side of which there is an adjustable nozzle spraying water to ensure the crystal of the cast bar close and equal.

The copper rod continuous casting and rolling line can be equipped with different kinds of melting furnaces according to various raw materials (copper cathode or red copper scraps).

The copper rod continuous casting and rolling machine, CCR line can produce ETP and FRHC with diameter 8 mm.

The copper rod continuous casting and rolling machine, CCR line is designed to produce φ8 mm low oxygen and bright copper rods by continuous casting and rolling.