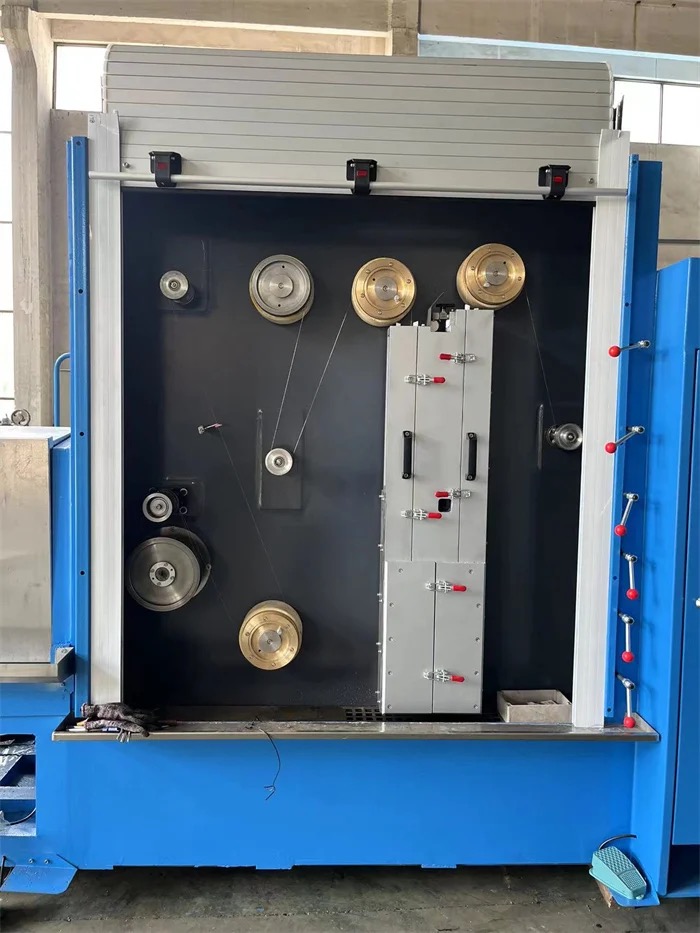

Mandy offers Wire Drawing Machine for a range of Single Fine Copper Wire. There are 4 sets Drawing Capstans (each on is with 11 grooves) are horizontally arranged in a row. There is a capstan at the output of drawing cabinet and it also works as a meter counter wheel. All of the Drawing Capstans are treated the ceramic coating on the surface for the purpose of wear resistance. We design the control system with PLC + HMI that makes the annealing current varies from zero to a setting current with the line speed in synchronization.

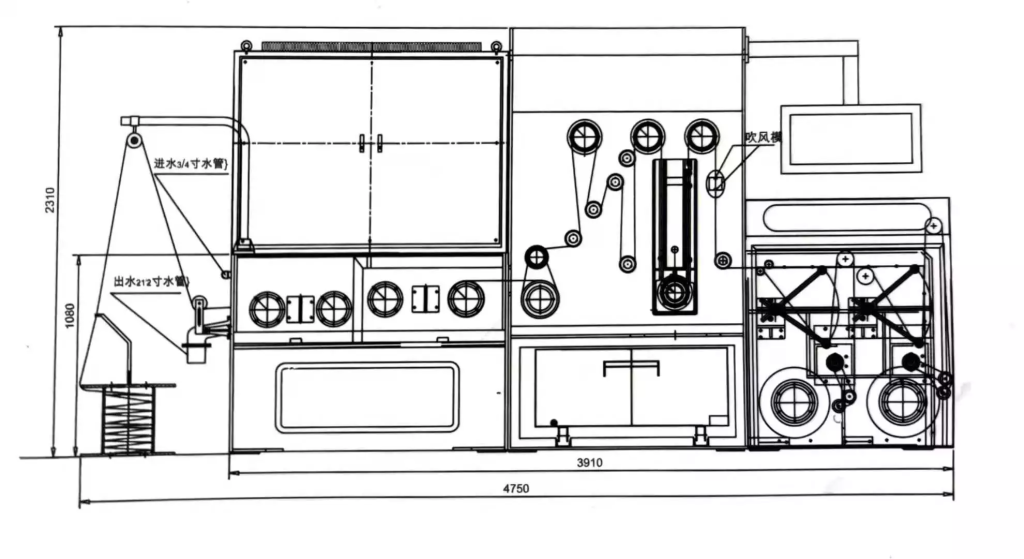

Fine wire drawing machine with annealer is special for drawing and annealing copper wires 0.5-1.38 mm from 0.10-0.40 mm. Finished wire is wound by 300 steel bobbin.

| Machine type | MF-B17 | MF-B20 | MF-14D | MF-B22 (MF-B22/A) | MF-B24 (MF-B24/A) | MF-22D (MF-22DA) | MF-24D (MF-24DA) |

| Inverter control | Double inverter control | ||||||

| Main machine structure | four cones in horizontal | two cones in horizontal | four cones in horizontal | four cones in vertical | |||

| Max. Inlet Dia. (mm) | Ф1.8 | Ф1.6 | Ф1.38 | Ф1.2 | Ф1.2 | Ф1.0 | |

| Outlet Dia. (mm) | Ф0.30~Ф0.70 | Ф0.30~Ф0.65 | Ф0.25~Ф0.50 | Ф0.1~Ф0.5 | Ф0.08~Ф0.32 | Ф0.10~Ф0.32 | Ф0.08~Ф0.25 |

| Max. Die No. | 17 | 19 | 14 | 22 | 24 | 22 | 24 |

| Max. Line speed (m/min) | 1500 | 1500 | 1200 | 2000 ( 2500 ) | |||

| Body structure | Welded | Ironed cast | |||||

| Drawing capstan | Ceramic plasma capstan | ||||||

| Slip ratio of m/c ( % ) | 15 | 13 | 15 | 13 | |||

| Main motor power (kw) | 18.5 | 15 | 15 | 11 ( 15 ) | 11 | ||

| Take-up motor (kw) | 5.5 | 5.5 | 5.5 | 4 | 4 | ||

| Fix speed capstan Dia.(mm) | Ф200 | Ф200 | Ф268 | Ф160 ( Ф206 ) | |||

| Transmission type | Belt | ||||||

| Take-up bobbin size (mm) | Ф300 / Ф400 | Ф300 | |||||

| Traversing type | Synchronous motor +belt | ||||||

| Tension control | Weight balance type | ||||||

| Lubrication type | Full immersion | Spray | |||||

| Brake | Magnetic Brake | ||||||

| Weight (KG) | 2600 | 2600 | 2200 | 2300 | 2300 | 2000 | 2000 |

Finished products by Fine wire drawing machine with annealer can be: