The graphite die is used in continuous up casting of copper tube, copper rod and strip, the graphite mould is with low air leakage rate, low air hole rate, high strength, high heat conductivity and extreme smoothness (Ra0.08) and results the casted tube or billet with smooth surface and be free of crack and air hole. The lifetime is twice of common graphite products.

The graphite mold is made from carbonaceous raw materials through a series of production processes. The compression molding process can adopt cold molding or cold isostatic pressing. The use of the most advanced high-tonnage cold isostatic pressing molding process can ensure the production of uniform, dense and high-strength continuous cast graphite. Adding surface coating technology can extend the service life of the graphite crystallizer, improve the quality of the continuous casting metal surface, and increase the speed of the continuous casting process.

| Density | g/cm3 | 1.7~1.91 |

| Specific Resistivity | μΩ·m | 8~9/ 13 /8~11 |

| Thermal Conductivity(100ºC) | W/m.k | 85~140 |

| Coefficient Thermal (-600ºC) | 10-6/ºC | 4.76~5.85 |

| Hardness | HSD | 40~70 |

| Flexural Strength | Mpa | 23~60 |

| Compressive | Mpa | 18~135 |

| Elasticity modulus | Gpa | 8~12 |

| Porosity | % | 11~18 |

| Ash Content | PPM | 500~1000 |

| Purification of Ash | PPM | 50 |

| Average Grain Size | μm | 0.8~2/12/8~10/13~15/20~25 |

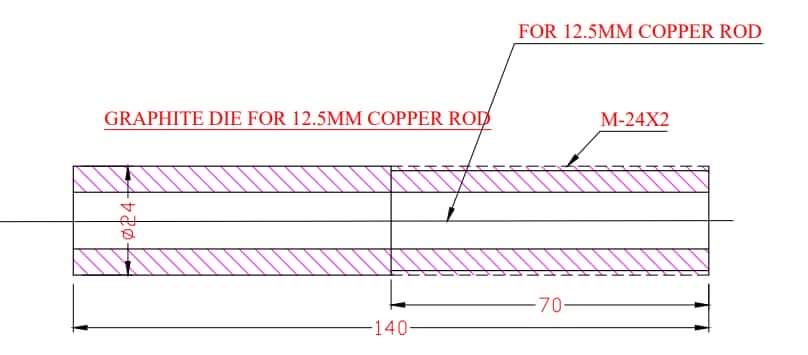

1. Copper rod continuous up-casting mould: 8 mm 12.5 mm 14.4 mm 16 mm 18 mm 20 mm 25 mm.

2. Copper tube continuous upcasting mould:48~55mm.